6 Things You Should Know about a Fiberglass Pool Gelcoat Surface

September 15th, 2018

6 min read

By Holly Jender

"Gelcoat" is a funky word to describe the surface of a fiberglass pool. Personally, it makes me think of the expensive nail polish option in a salon. Plus, "gel" sounds like it'll be soft and squishy—not the ideal texture for a pool. So what gives? What is a gelcoat, really?

Here at River Pools, we specialize in fiberglass pools, so we know them inside and out (literally). We want to share our knowledge so that you can be fully informed when you make that big pool decision for you and your family.

Let's start at the beginning: the gelcoat surface.

What you should know about fiberglass pool gelcoats:

- What they are

- How they're applied

- How they're tested

- How they compare to a plaster finish

- How they compare to a vinyl liner

- What makes River Pools different

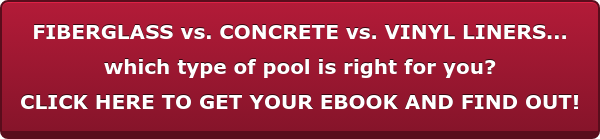

1. What a gelcoat is

Gelcoat is a colored resin. It creates the surface layer of a fiberglass pool—the inside part, which you see when it's installed in your backyard.

Pro tip: If you're looking at a fiberglass pool shell, just look for the pretty side. That's the gelcoat.

It's a liquid, so we store it in drums. But when it's time to rock and roll, we spray it on with compressed air.

2. How gelcoats are applied

We apply the gelcoat with compressed air and a spray gun.

Compressed air is the driving force behind the gelcoat application. It's important that the air is clean and dry, so it goes through several steps of purification before it meets the resin.

You want your gelcoat applied in 3 passes, resulting in a total thickness of 25–30 mils.

This may not seem like much, but the range is critical!

Too thin, and it could get blisters due to an improper cure.

Too thick, and it could crack.

Fun fact: The pool shell isn't the only place we use a gelcoat. The mold itself has a gelcoat finish too!

3. How gelcoats are tested

You may have heard about boiling gelcoat to test it. (This isn't completely accurate—we don't submerge it.)

We boil water and put a piece of fiberglass pool shell on top. The steam reacts with the gelcoat surface.

When we take the test piece of shell off the water, you can see the difference between the regular gelcoat and the circle from the steaming pot.

Why do we bother?

The accelerated reaction reveals how the surface will perform under stress over time.

It shows how much the color will fade, if osmotic blisters form, and so on.

4. Fiberglass pool gelcoat vs. concrete pool plaster surface

Fiberglass pools vs. concrete pools

- Texture

- Appearance

- Maintenance

Texture

The gelcoat of a fiberglass pool is smooth to the touch. Even textured surfaces (like the steps) aren't rough, just anti-slip.

By contrast, the plaster surface of a concrete pool is so rough it can actually draw blood. This is bad enough for adults, and even worse for small kids.

Durability

You don't have to worry about regular wear and tear damaging a gelcoat or plaster pool surface.

Both options are super durable!

Maintenance

Plaster's porosity invites algae, so you need to steel brush it weekly and acid wash it every 3–5 years. Every 10–15 years, you need to replaster the pool and replace the waterline tile. Booo.

A gelcoat is much less porous, so algae doesn't bother it. With proper manufacturing and maintenance, it will never need to be refinished.

5. Fiberglass pool gelcoat vs. vinyl liner pool surface

Fiberglass pools vs. vinyl liner pools

- Texture

- Durability

- Maintenance

Texture

A fiberglass pool gelcoat is smooth, and so is a vinyl liner, other than the ridge where one piece meets another.

Both are pleasant to touch!

Durability

If manufactured correctly and maintained properly, a fiberglass pool gelcoat will never need to be refinished. It's also strong enough that dog claws, stray tree branches, and other day-to-day wear won't damage it.

A vinyl liner has to be replaced every 5–9 years. It can easily be punctured or torn before then, too. Dogs shouldn't walk on the steps or tanning ledge, as their claws can poke holes.

Maintenance

The gelcoat surface is smooth and algae-resistant, so algae has nowhere to grow.

A vinyl liner is also smooth and relatively algae-resistant, but algae can pop up in seams and corners where water doesn't circulate.

6. What makes River Pools different?

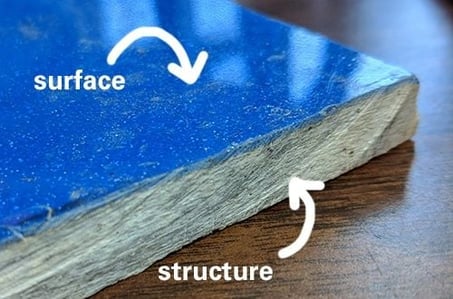

At River Pools, we manufacture world-class fiberglass swimming pools for installation across North America and have a wide variety of models to choose from. Our dedication to quality continues the legacy of our brand.

The River Pools Way is a commitment to not cut corners.

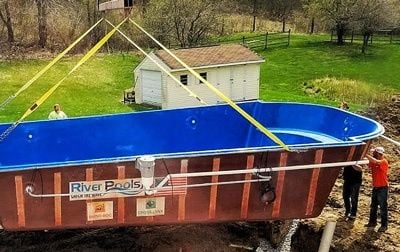

Ready to flash back to high-school chemistry class? Don't worry; it'll only take a second.

Quick reminder: everything is chemicals. Woo, science!

Individual molecules cross-link with each other to form chains. We call that cross-linking polymerization, because they're forming a polymer. (No worries: there won't be a spelling quiz.)

The more the molecules bond, the stronger and more durable the final product is.

Our series of manufacturing best practices promotes polymerization—the key to building a durable fiberglass pool that will stand the test of time in your backyard.

Catalyst concentration

The gelcoat catalyst initiates the cure. Too much, and the gelcoat cures too fast. Too little, and the gelcoat doesn't achieve a full cure.

The catalyst needs to be in a concentration of 1–2%, depending on environmental conditions.

We set the catalyst concentration before spraying each pool to ensure the gelcoat will achieve an optimum cure and stand the test of time.

The perfect temperature

Temperature is critical. The optimum temperature for spraying gelcoat and other resins is 77°F.

We control the temperature of the facility, the gelcoat material, and the mold to ensure temperatures stay within the optimum range.

Air system

Moisture is bad news for resin and gelcoat. Water introduced at any point in the construction of your fiberglass pool could prevent a full cure.

What does that mean? The gelcoat finish or another resin may not be as durable as it should.

The products are applied by air, so the product is only as good as the air it's applied with. If there's water in the air from the compressor, there's water in the pool shell. And that's just not okay with us.

We have a state-of-the-art air compressor that powers all our spray guns.

On top of that (almost literally, in the shop), we use an air dryer and multiple water separators to remove the water and other contaminants from the air.

So the air comes out of the compressor, through a separator (to pull moisture out of the air), through the dryer (to dry it again), and through another separator (to dry it AGAIN), before that air reaches a spray gun.

Y'know, I think it's dry now.

No mold blemishes

If you apply the gelcoat on a mold that has blemishes, the pool will have blemishes.

We use the highest-quality materials we can buy, but a bad mold will always, always produce a bad pool shell. No exceptions.

That's why we ensure that each mold is blemish-free before we build a pool on top of it.

Ground-breaking best practices for installation

Our unique installation methodology prevents the most common issues with fiberglass pools:

- Settlement or shifting of the pool shell

- Leaks in plumbing lines and around jets and other pool fittings

- Separation between the pool and patio

- Bulges in the side walls of the pool

We developed our River Rod to fuse the fiberglass pool shell and patio together. This prevents shifting, settlement, or movement of any kind that could result in structural failure.

We secure the plumbing by fastening the pipes to the pool shell with a strap system. This ensures no stress is placed on any component of the plumbing system.

We use only hard PVC pipe—flexible piping is easier to use, sure, but it's not rated for underground use. We don't take risks with your pool.

We use clean, crushed stone under the pool and around the outside of the pool shell. The plumbing is encased in stone as well, which prevents plumbing settlement. The right stone backfill won't move or settle, drains better than sand, and doesn’t change its properties when wet.

We pour a 12”-thick concrete bond beam around the perimeter of the pool, going under the lip of the pool shell and encasing the River Rod. This locks it all into place.

We include a sump pipe so you can monitor and remove groundwater, preventing any issues from hydrostatic pressure.

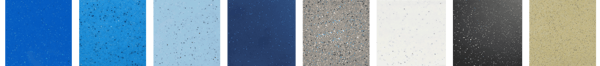

Shimmer finishes

Okay, so this one isn't necessarily scientific. But sparkles are the best!

Our pool colors are shimmery and delightful:

- Maya Shimmer

- California Shimmer

- Caribbean Sparkle

- Azure Shimmer

- Granite Grey

- Arctic Shimmer

- Midnight Shimmer

- Sandstone Shimmer

Up Next:

What Is a Fiberglass Pool Mold?

The Pros and Cons of Fiberglass Pools

Editor's note: This blog article was updated on March 25, 2019.

Editor's Note: This article was originally written by Holly Jender on August 29, 2018. Any opinions expressed are those of the author. Any prices referenced were based on information that was readily available at the time.

River Pools is a brand of inground fiberglass pools produced in a manufacturing facility in Fortville, IN. While our expertise is in manufacturing fiberglass pools, we have access to a network of installers with expertise relating to project design, installation, and pool service. We often tap into this knowledge base and share information freely with homeowners, just like you, considering installing a swimming pool in your backyard.