Vinyl Liner Pool Basics: Pros, Cons, and How They’re Made

December 9th, 2017

8 min read

By Holly Jender

Most of us have been around vinyl liner pools at one time or another. (For example, my grandparents have one. I now know that they needed to replace the liner years ago. Don't blame the grandkids for rusted wall panels, Nana.) But personal experience doesn't necessarily mean someone knows the details. Curious about the basics?

Here at River Pools, we worked exclusively with them for years before we discovered and fell madly in love with fiberglass pools. We’re all about making information available to you and easy to understand. That includes all types of pools.

Here’s what you need to know about vinyl liner pools:

- Components

- Cost

- Pros and cons

- Construction process

What is a vinyl liner pool?

A vinyl liner pool has five main components:

- Wall panels

- A pool base

- Vinyl liner

- Steps

- Coping

Wall panels

The wall panels—surprise!—make up the walls of your pool, everywhere except the steps. The most common material options are steel, aluminum, or polymer (plastic).

These wall panels are typically 42 inches tall, so the shallow end of vinyl liner pools are typically that depth.

Pool base

A pool base is typically made of vermiculite or grout.

You apply the material mixture on top of the soil with a round-edged pool trowel, and then install the liner on top of it.

Vinyl liner

To state the obvious, the liner is made of vinyl.

The thickness is measured in mils—which is not the same as a millimeter. I know; they should have thought that through better. A mil is 1/1000 of an inch, also called a “thou” (as in a thousandth).

Vinyl liners for inground pools are usually 20, 27, 28, or 30 mils thick—less than a millimeter.

Another unit of measurement is the gauge, which varies in size depending on the dealer. If a measurement is in gauges, ask for it in mils to be sure it’s what you need.

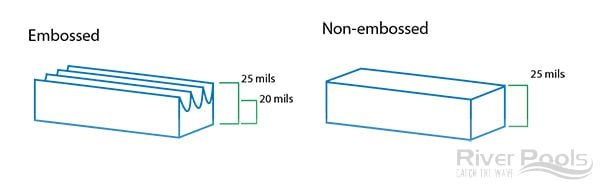

The vinyl liner will either be embossed or non-embossed (standard).

Embossed liners feel soft because they vary in thickness, with peaks and valleys. They’re measured by the highest peaks of the liner, not by the lower solid part—meaning if a liner is “25 mils embossed,” it won’t be 25 mils high all the way across the top.

Non-embossed liners doesn’t feel as squishy because they’re flat across the top. This option is equally thick all the way through.

The economic option for a vinyl pool liner is 20 mil embossed.

Thinner liners can tear or puncture easily, but they’re also inexpensive and easier for builders to work with.

Thicker liners cost more and are harder to handle, but they provide extra protection against dog nails or that pointy toy your toddler threw into the pool.

We recommend using a thicker vinyl liner because it acts like a good insurance policy. Problems may still show up, but thicker vinyl provides additional protection from the worst damage.

Steps

There are three common types of steps for a vinyl liner pool:

- White plastic steps

- Vinyl over steps

- A ladder

White plastic steps are the standard for vinyl liner pools. They’re made of polymer, are attached to the pool walls, and jut out from the main body of the pool.

Vinyl over steps are premade, with many options available. You buy the liner to fit over the steps.

A ladder is, well, a removable metal ladder that you install into the patio. It hangs over the edge of the pool.

Coping

Coping is the border around the top perimeter of the pool—the transition from the pool to the patio. For vinyl liner pools, the standard is white aluminum C-channel coping.

The aluminum can be painted different colors, but white is the most common.

The term C-channel (or U-channel) means that it’s bullnose (or half-round, like a C shape) coping that’s bolted at the top of the pool wall panel as a permanent border for the patio concrete.

For comparison:

- For cantilevered coping, the builders pour patio concrete up to a styrofoam form at the edge where the pool meets the patio. When they remove the form, the concrete itself is the edge (often bullnose).

- Flat-mount coping is flat and just secures your vinyl liner. You can add different coping, like fancy pavers, on top of it.

Average cost of a vinyl liner pool

The initial cost of a pool is what you pay upfront when you buy it—the pool itself, any cool features, and the surrounding area.

The lifetime cost is what you spend after the purchase—maintenance, repairs, and replacements.

Initial cost

An inground vinyl liner pool usually costs $45,000–$80,000 at the initial purchase.

These factors influence the upfront price:

- Region

- Size

- Shape (rectangular or freeform)

- Features

- Vinyl liner thickness

- Type of steps and benches (plastic or metal)

- Type of coping (concrete or natural stone)

- Type of wall panel (steel, plastic/polymer, or aluminum)

- DIY vs. professional installation

Lifetime cost

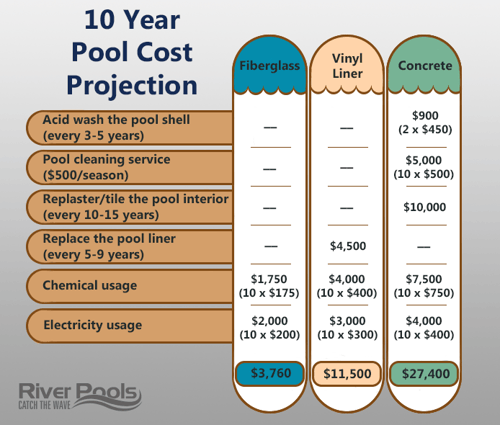

On average, a vinyl liner lasts 5–9 years. Each time you replace it, you pay about $4,500 altogether for labor, materials, water, and chemicals.

Vinyl liner pools require less electricity and fewer chemicals for day-to-day maintenance than concrete pools because they’re less prone to algae. However, pool chemicals and electricity will still cost you about $7,000 over a 10-year period.

Pros and cons of a vinyl liner pool

Vinyl Liner Pool Advantages

- Low initial cost

- Quick construction

- Customizable shape

- Smooth liner surface

- DIY option

Low initial cost

Vinyl liner pools are super budget-friendly. Most cost at least $10,000 less than similar fiberglass or concrete pools.

Quick construction

Building a vinyl liner pool only takes 4–8 weeks.

This isn’t as fast as the 3-6 weeks for a fiberglass pool (and you can swim by day 2), but it’s much faster than the 3-6 months for a concrete pool.

Customizable shape

The vast majority of vinyl liner pools are rectangular, but you can definitely customize the shape, size, and depth of the pool.

Custom shapes cost more, but still typically less than a similar fiberglass or concrete pool.

Smooth liner surface

A vinyl liner is smooth other than the slight ridge where one piece of material meets another. Compare this to a concrete pool, which is rough enough to scrape your skin unless you pay big money for an all-tile or polished interior finish.

DIY

You can DIY a vinyl liner pool, saving $10,000–$15,000. Some people do the most basic work and pay professionals to do the more skilled areas. Others like to install the entire pool themselves.

Keep in mind that this will probably take longer than hiring a professional, and you run the risk of inaccuracy.

DIY also makes it harder to have a specialty freeform curve because you’d need to cut the liner specifically to fit the fancy design, which would be not only a pain but also near-impossible to do accurately.

Vinyl Liner Pool Disadvantages

- Not pretty (white coping and steps)

- Not durable

- Liner replacements

- Liner warranty not straightforward

- Metal walls incompatible with salt water systems

- Not ideal for high water table areas

Not pretty

Standard vinyl liner pools include white coping and big plastic white steps that jut out from the body of the pool. They advertise that it isn’t a classic concrete or fiberglass pool.

Fancy customized vinyl liner pools can be lovely, though!

Not durable

Vinyl liners for inground pools are usually 20, 27, 28, or 30 mils thick—less than a millimeter. Dog claws, a broken branch, or even hungry insects can tear that pretty easily.

Wrinkles in your vinyl liner won’t hurt anything, but if you choose to smooth them out, that takes significant time and effort.

Divots and dents are usually cosmetic issues as well, but a bump due to a rock or pebble could lead to a tear in the liner. For these issues, you have to drain the pool and remove the liner for repairs.

Liner replacements

Today's vinyl liners typically last 5–9 years, at $4,000–$4,500 for each replacement. This includes the cost of the liner, labor, water to fill the pool, and other minor expenses.

Thanks to these replacements, the low initial cost of the pool could be off-set within the first ten years after construction. Over the entire lifetime of the pool, it will cost many thousands more than a fiberglass pool.

Liner warranty not straightforward

If you expect to receive any credit on a liner replacement, be sure to read the warranty in full. You'll probably find the following information:

- The warranty only covers the "seams" of the liner, where the sections of material are fused together.

- The warranty does not cover any labor, water, or other expenses.

- The warranty is extremely pro-rated. You'll get some credit toward a new liner during the first two or three years, but next to nothing after that.

Not compatible with salt system

You can use a salt water system if your vinyl liner pool has polymer wall panels, but not if you have metal wall panels. The salt corrodes the panels and any handrail and ladder anchors made of galvanized steel (use bronze).

Parts of Vinyl Liner Pools Do Harbor Algae Growth

Algae can grow in submerged areas of the pool that don’t circulate water. parts of the pool like where the white plastic steps attach to the pool wall, and behind light niches have submerged areas that do not have circulated water.

How vinyl liner pools are made

It generally takes 4–8 weeks to build a vinyl liner pool.

Phase 1: Vinyl Liner Excavation

When excavating for a vinyl liner pool, the builders dig the hole about 30 inches larger than the finished pool around the entire perimeter. The space is for the vertical braces that support individual wall panels.

Some builders dig the entire hole initially, including the deep end. Others excavate in two phases, digging enough to install the perimeter wall panels first, then commencing excavation of the deep end.

Duration: 1–2 days

Phase 2: Wall Panel Assembly

The builders bolt the pool wall panels together and secure them with braces for support.

They assemble any plastic or fiberglass steps or “buddy seats” at this stage as well.

Duration: 1 day

Phase 3: Concrete Footing

After the builders assemble the perimeter wall panels, the footing inspection must be approved.

Then the builders pour an eight-inch deep concrete footing around the outside perimeter of the structure to lock the wall panels in place.

Duration: ½ day

Phase 4: Vinyl Liner Pool Plumbing

The builders install plumbing around the pool and to the pump and filter system.

Duration: 1 day

Phase 5: Vinyl Liner Pool Base Installation

Now they lay down the material that covers the exposed earth and that the liner rests upon. They mix this material (typically vermiculite or grout) and then trowel it in place.

Duration: 1–2 days

Phase 6: Installation Of The Liner

The top of the liner has a “bead” that inserts into a track mounted to the top of the wall panels. The builder places the liner into the pool, “snaps” it into place, then form-fits it to the shape of the pool using a vacuum to remove the air behind the liner.

Once the builders adjust the liner to remove wrinkles, they start filling the pool with water.

When there’s enough water to hold the liner in place, they cut the holes for any skimmers, lights, return jets, or the pool steps are cut and faceplates installed to hold the liner in place.

They then completely fill the pool with water.

Duration: 1 day

Phase 7: Vinyl Liner Patio Installation

This stage first requires a bonding inspection.

Some contractors complete the patio surround before installing the liner, and others install the pool first.

They must ensure that the material beneath the patio is stable (properly compacted). If they backfill with the original dirt without using proper compaction methods, there may be structural patio problems down the road.

Duration: 1–2 weeks

Phase 8: Vinyl Liner Pool Start-up

The builders and/or you will test and adjust water chemistry to bring it within accepted ranges and will clean the filter as needed upon start-up until the water is clear.

Duration: 1–2 days

Other options for an inground pool

Now you know the components, cost, pros and cons, and construction process for a vinyl liner pool. Still, this isn’t everything you need to know to make your decision.

To ensure you’re getting the best value and the best fit for your situation, compare the pros and cons of fiberglass, vinyl liner, and concrete pools. For example, you’ll see that fiberglass pools keep most of the positive characteristics of vinyl liner pools and avoid the negatives.

At River Pools we offer fiberglass pools throughout the country via independent installers. If you think a fiberglass pool might be the right choice for you, we want to answer any questions you have! Feel free to ask us questions in the comments, or click the button below to reach out and request pricing:

Be sure to download your free ebook below before you go for an in-depth comparison of the three main inground pool types. Happy swimming!

Up Next:

How Long Do Vinyl Liner Pools Last?

Inground Pool Shopping: Can You Buy a Pool Online?

Your Swimming Pool Color Options: Concrete, Vinyl Liner, and Fiberglass

Editor's note: This article was updated on September 1, 2023.

Editor's note (5/17/24):

This article was originally written by Holly Jender. Any opinions expressed are those of the author. Any prices referenced were based on information that was readily available at the time.

River Pools is a brand of inground fiberglass pools produced via the River Pools division of the manufacturing facility in Fortville, IN. While our expertise is in fiberglass pool manufacturing, we have a network of expertise relating to all things inground pools. Our own collective experience from over the years spans manufacturing, project design, installation, and pool service. We often tap into this knowledge base and share information freely with homeowners, just like you, who are considering having a swimming pool installed in your backyard.